Confined Spaces & Gas Detection Solutions for Worksite Safety

Entering and working in confined spaces poses serious risks to personal safety including entry/exit and exposure to harmful gases. Accurate detection of and protection against harmful gases is mission-critical for safe and effective confined space work.

URSafeRite’s comprehensive range of confined space equipment and gas detectors provides essential protection that is perfect for industrial safety teams, maintenance & demolition workers, and confined space entry crews. Safe entry/exit methods are assured using our tripods, descent systems and fall arrestors. Our confined space gas detection gear provides accurate tools for detection and measurement of gases and vital oxygen levels.

Our range provides reliable, tested and certified gear fully compliant with safety standards to ensure the ultimate in protection for the most demanding confined space work applications.

Why is gas detection critical in Confined Spaces?

Confined space work in tight spots is challenging. A critical risk is the presence of harmful toxic gases which if not managed can cause explosion or poisoning. Safety regulations and legal requirements demand that prevailing air quality be tested and assessed before confined space work is conducted.

Gas detection is necessary to identify and measure the presence of toxic and/or combustible gases, and the oxygen levels present within a confined workspace. Low oxygen levels can be life-threatening if not detected, monitored and supplemented.

Accurate gas detection enables informed and considered decisions for the selection and use of appropriate personal protection, such as respiratory equipment, that must be utilised before entry and during work in confined spaces.

Features of Our Confined Space & Gas Detection Equipment

URSafeRite’s range is packed with advanced features trusted by professionals to deliver the ultimate in personal protection for confined space work.

Our confined space equipment provides safe and controlled entry/exit methods when utilising tripods, winches & descent systems, fall arrestors, and rescue kits.

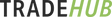

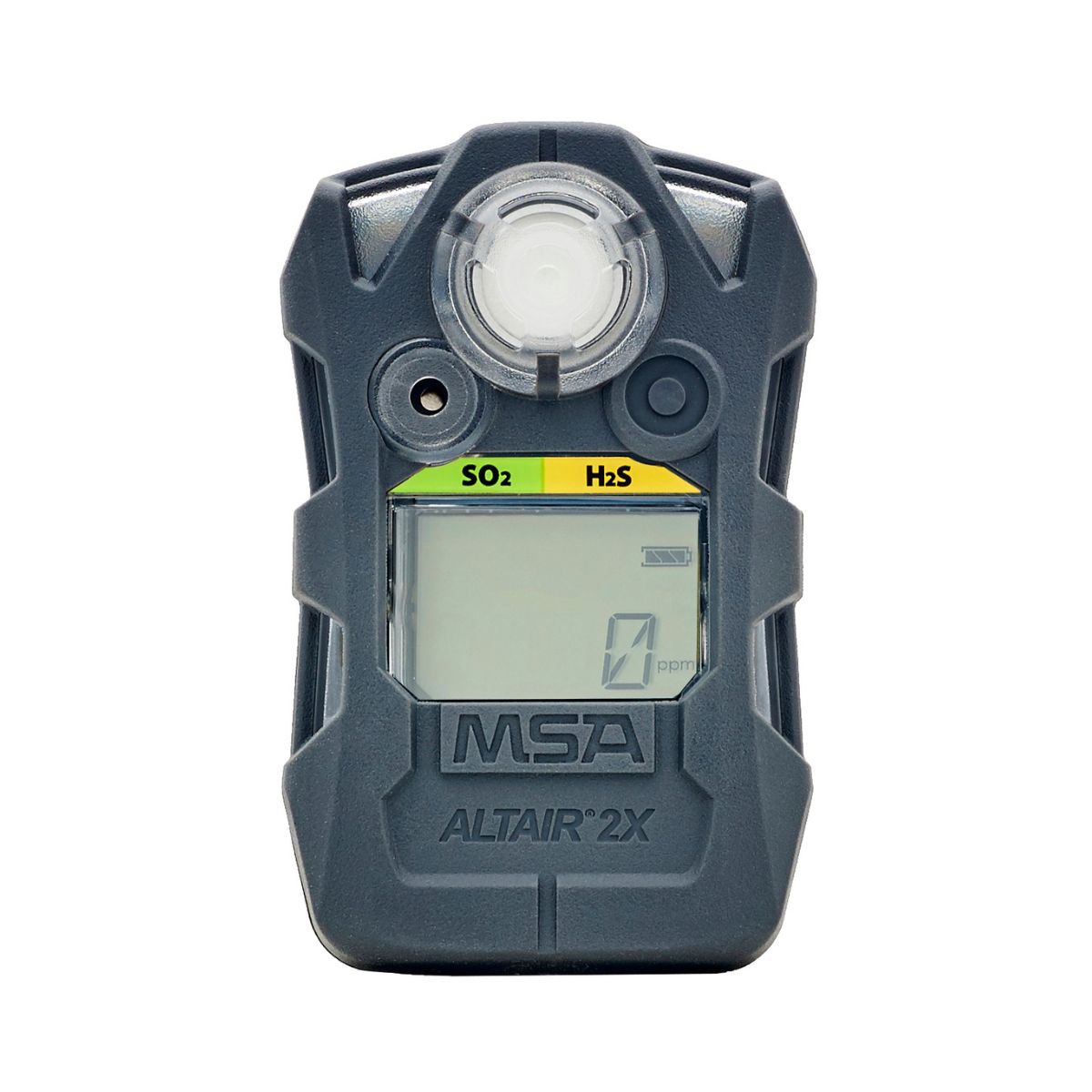

We offer best-in-market gas detectors to measure single gas (e.g. CO or O2) or multi-gas with advanced technology including real-time monitoring and alarms, plus data-logging and calibration options. Our range also features calibration gas and test systems to ensure ongoing accuracy & reliable performance from your gas detection equipment.