Buy Metal Detectable Products

Metallic foreign objects & particles are a major contamination risk in food & pharmaceutical consumer goods. Metal detectable products are widely used in the food processing and pharmaceutical sectors to help identify & remove contamination risks from foreign objects during manufacturing and production line processes.

Advanced detection machinery is utilised in these industries at critical control points during production to detect the presence of foreign objects such as metal particles, which pose significant risks to consumer safety, and also cause operating downtime and product recall risks.

URSafeRite’s range includes metal detectable earplugs, metal detectable scissors and stationery, and metal detectable nitrile gloves for versatile use and ready detection in the food and pharma industries.

Ensure precaution and due diligence in sensitive consumer manufacturing operations and check out URSafeRite’s comprehensive range of metal detectable products today. Maximise workplace compliance and protection with our complete range of workplace site safety.

Why Metal Detectable?

Common sources of contamination risks in consumer goods comes from machinery wear & damage; accidental breakage & drops; and worker mishandling or loss of tools & PPE used during production.

Metal detectable products are designed to promote production line safety and efficiency by helping to identify & remove contamination risks, in order to protect consumers and to maintain brand integrity by reducing the risk of expensive product recalls.

Use of items required during processing operations which contain detectable additives, such as metal detectable stationery, earplugs, tools & PPE, allow these items to be picked up by metal detection or X-ray systems, meaning that contaminating fragments or particles are prevented from reaching finished products released to consumers.

Metal Detectable Product Categories

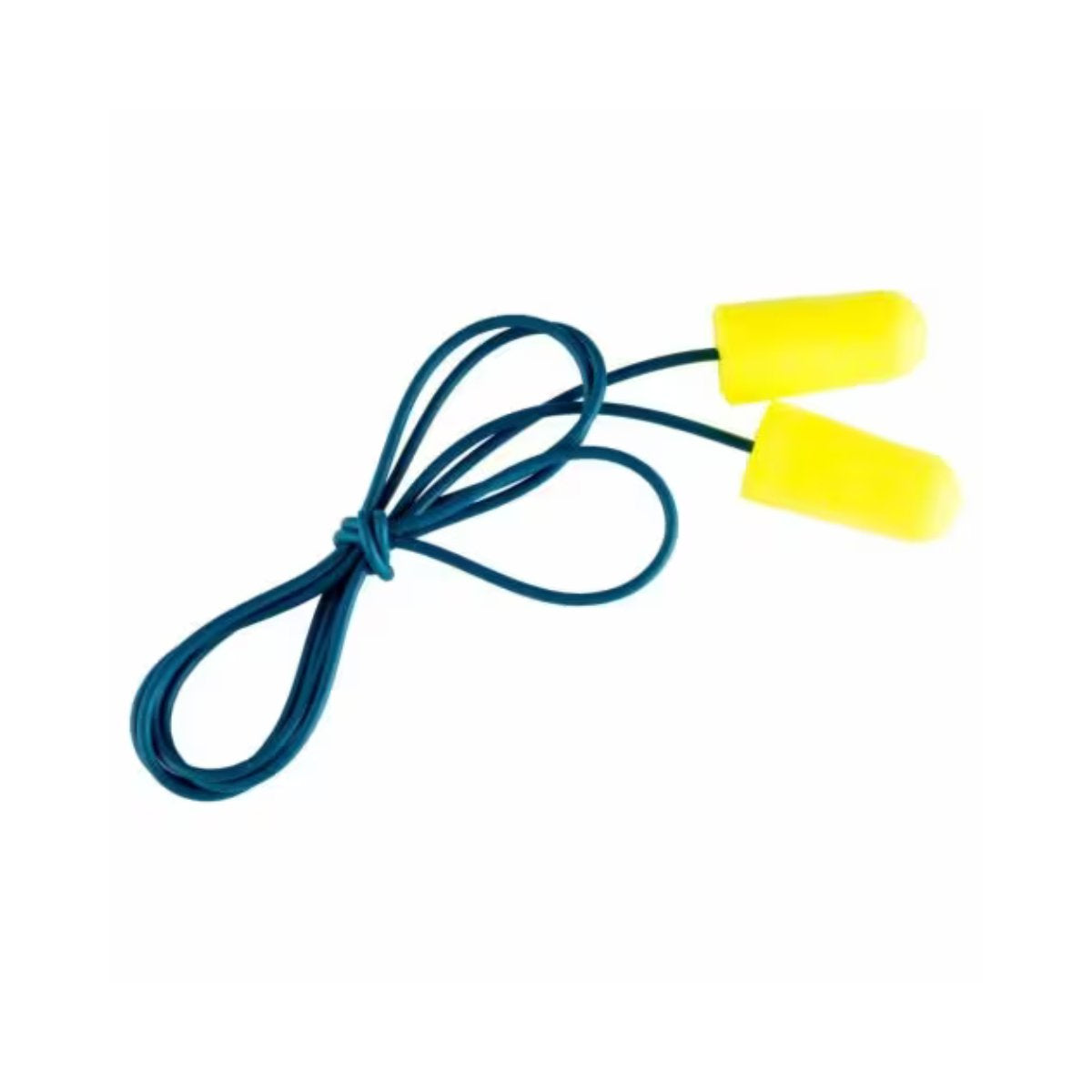

PPE such as metal detectable ear plugs (corded & uncorded models) are widely used in food processing and pharmaceutical sectors to enhance worker safety and also provide consumer protection by reducing contamination risks during production line operations. Metal detectable nitrile gloves provide workers with strong & food-safe hand protection for processing tasks and ensure these items are detectable at critical control points.

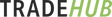

Metal detectable tools (such as scrapers, cable ties, scoops and scissors) are used for food preparation and processing operations, and quality assurance finishing tasks. Use of these items allows any metal fragments to be detected before processing is completed for consumer goods.

Metal detectable stationery (such as pens, markers, clipboards) is designed to reduce the risk of foreign matter contamination during production environments, and is available in different colours for effective task coding & identification in manufacturing environments.

Selection & Implementation Tips

There are a range of factors that must be considered regarding the selection & implementation of metal detectable products, including:

- Detection technology to be utilised: Metal detection or X-ray? This depends on the types of contaminants to be detected & production environment characteristics. Metal detection systems are more cost-effective, however more limited compared to X-ray systems.

- Detection positioning: Dependant on the number and location of critical control points needed to detect contaminants during processing stages.

- Colour coding requirements: Is this required? If so, range of colours?

- Range, size & fit of metal detectable PPE required for line workers.

- Testing & validation on individual production lines: Product samples should be obtained & tested to confirm detection accuracy & equipment calibration for each processing line.

- Documentation required: for testing & audit retention.

Why URSafeRite

URSafeRite’s comprehensive range provides compliant & certified metal detectable products for versatile use and ready detection in the food and pharmaceutical industries. We can provide bulk pricing and prompt delivery Australia-wide for your metal detectable product requirements.